PRODUCTS

Process principle

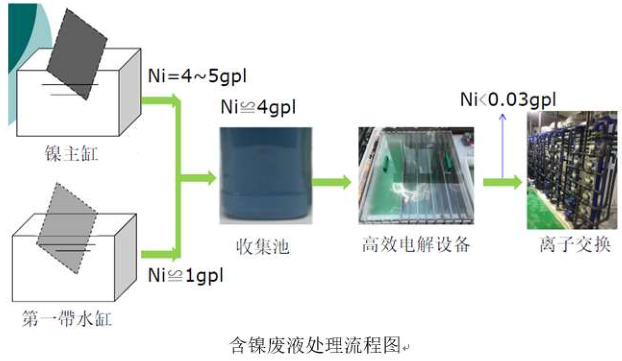

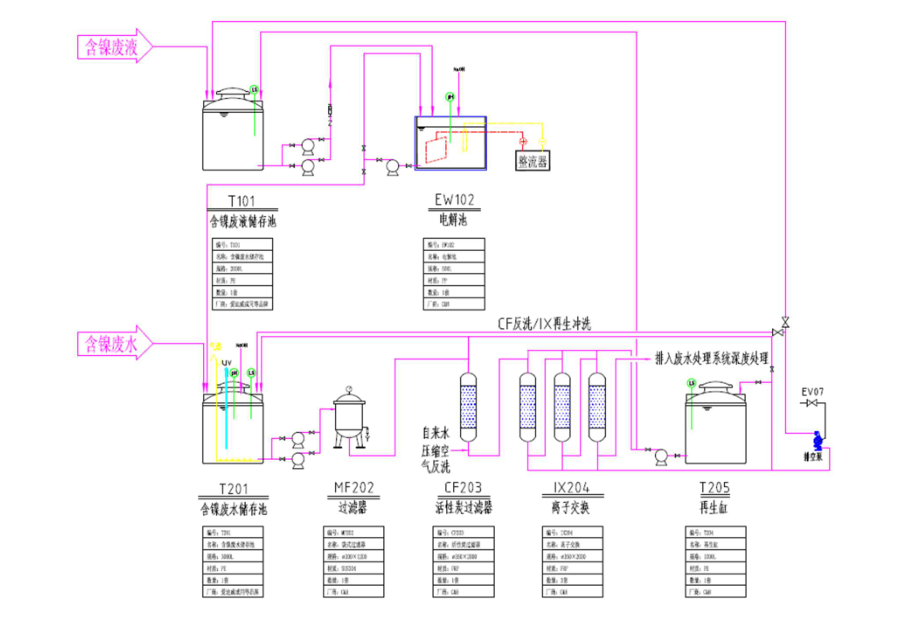

1、Collect and store the waste liquid from main cylinder which contains 4-5g / L nickel content and the waste liquid from the first filtered water cylinder which contains 1G / L nickel content together.

2、The waste liquid from step one will be sent to the electrolyzer to adjust the PH value and get electrolysis. The nickel content in the tail liquid is about 60 ppm after get electrolysis.

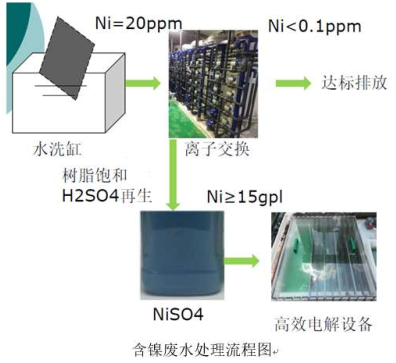

3、Collect the waste liquid from step two and the waste liquid from filtered water cylinder which contains 20 ppm nickel content together and store it into the storage tank.

4、After step three ,the waste water with nickel content will be treated by activated carbon adsorption and exchange nickel ions in exchange resin towers. Then,the effluent will be discharged to the sewage treatment station for treatment of TP(total phosphorus), COD (chemical oxygen demand) and PH (PH).

5、Ion exchange resins need to be regenerated after using for a certain time. Regenerative waste liquid with nickel content need to be returned back to step two for electrolysis. And add dephosphorization agent so that we can precipitate and remove total phosphorus.

6、If the waste water treatment station can not deal with the TP of waste liquid from step four. Fenton technology can be used to oxidize hypophosphite to orthophosphate.

System features

1、We design three ion exchange resin towers, two for use and one for standby or regeneration. Two of the towers which are used will be designed to operate in series connection, so that it can ensure stable and reach the standard.

2、Recycling and regeneration mode, recycling waste liquid treatment; recycling and cleaning waste water is collected and enters the ion exchange resin tower for treatment afterward.

3、UV germicidal lamp is installed in the waste water collection pool to effectively reduce bacterial reproduction, and prevent bacteria or bacterial corpses from blocking the active carbon and ion exchange resin towers.

4、The activated carbon filters are used for primary filtration, which is conducive to the removal of some organic matters and colloids. After primary filtration, the wastewater enters the ion exchange resin towers.

5、We strictly control the pH value of influent water to ensure the stable operation of ion exchange resin

6、The process of control and online monitoring system was strengthened because of the design of the system, and the online monitoring equipment was provided by us.

Process explanation chart

Process flow chart

Pictures of the scene